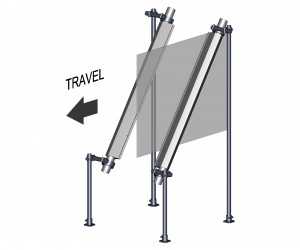

The picture shows a typical setup for drying hanging parts. Imagine the part is a flat sheet of glass. If the air knives were mounted straight up and down, they would blow the water toward the back end of the d be trying to blow the water around the edge and onto the other side of the glassglass. When the back end passed between the air knives, one air knife woul. The other air knife would be doing the same thing. In that situation, there is usually a bead of water left hanging along the entire back edge. If you angle the air knives as shown in the picture, then the air knives sweep the water down along that back edge. If any water is left, it is only a drop on the lower back corner.

We have used glass as an example, but the same general principle applies to many differently shaped parts. This kind of air knife setup is often used to dry parts that have gone through a washer on an overhead conveyor. In that situation, it is common to have to dry many different sizes and shapes. The air knives have to be placed to allow the widest parts to pass. This means the air knives can be some distance away from the narrowest parts. For this reason, these systems usually have to operate at higher velocities and may require more passes, four or six or eight air knives instead of just two. Complex shapes may require the addition of nozzles to treat difficult areas such as blind holes where water can be trapped.